What is Lean Six Sigma : by John Dennis MBA PMP ICBB

1. What is Lean Six Sigma ?

Most of its principles, methods, tools and techniques have been developed over many decades and even centuries…however the term ‘Lean’ developed out of the effective implementation of these principles, methods, tools and techniques by Toyota car manufacturing in the 1960’s, 70’s and 80’s and the term ‘Six Sigma’ was coined by Motorola in the 1980’s as the name for their Quality improvement program. Six Sigma, a data-driven approach to eliminate defects in processes, was introduced and developed at Motorola. Statistical analyses of processes are combined with organizational rewards. Six Sigma evolved side-by-side with Lean, and although once independent entities, they are now combined.

2 : How does Lean Six Sigma help businesses ?

Lean Six Sigma specifically offers the following benefits:

- Improved Quality of products and services

- Lower amounts of defects, scrap and rework

- Improved delivery times

- Reduced waiting times

- Reduced costs

- Improved customer satisfaction

- Improved employee morale

3 : Who uses Lean Six Sigma ?

Lean Six Sigma is used by both manufacturing and service industries across all sectors and all sizes of business.

- Manufacturing

- Health Services

- Financial Services

- Retail

- Government Services

- Education

- Oil and Gas Services

- Logistics and Supply Chain Services

Many of the World’s top organizations run Lean Six Sigma programs.

For example :- Samsung

- Xerox

- Denver Health Care

- Caterpillar

- U.S. Army ( United States Military )

- General Electric

4 : What is Six Sigma ?

Six Sigma is a well defined, customer focused management system that strives for the delivery of near-perfect products or services. Six Sigma’s goals are to reduce defects and variation so that processes are more consistent and predictable. Originated by Motorola in the 1980s, and successfully used and promoted by both General Electric (GE) and Honeywell ( Allied Signal ) in the 1990’s, Six Sigma is now used in many diverse industries from Auto Manufacturing to Healthcare to Pharmaceutical companies. Like Lean, Six Sigma places the customer first. It embraces data and more advanced statistical methods to make sound decisions as to the true root cause of problems and variation within processes. What has made Six Sigma so popular is the money it has saved companies in the reduction of their ‘Cost of Poor Quality’ (COPQ), from previous industry estimates of over 25% ( of total production costs ) down to less than 1% for true ‘Six Sigma’ companies. Six Sigma follows the DMAIC ( Define, Measure, Analyse, Improve and Control) methodology for problem solving in processes and the reduction of variation. This is sometimes a better approach than the more traditional PDCA ( used in Lean ) due to the emphasis on measurement of data from the process and statistical analysis of the data as a means to determining the root cause of the problem and variation. Six Sigma also focuses on Statistical Process Control ( SPC ) methods for monitoring and controlling processes to ensure that they continue to be stable and predictable.

What is Lean Six Sigma?

Peter Sherman, CMBB, CQE, CSCP

First Published :Quality Magazine : July 7th 2014

Let's review what is Lean Six Sigma.

Lean focuses on value through the relentless elimination of waste and acceleration in the velocity of processes. Its origins can be traced to Henry Ford of Ford Motor Company and Taiichi Ohno of Toyota. Value is defined in terms of what is important to the customer. Value-add work is something your customer is willing to pay for. For example, does the task add a desired function or feature to the product or service? Or does the task enable a competitive advantage (faster delivery, fewer defects, lower price)? Non-value work, or waste, includes activities the customer is not willing to pay for.

There are eight commonly known forms of waste that can be remembered using the acronym DOWNTIME: Defects, Overproduction, Waiting, Non-Essential Processing, Transportation, Inventory (too much or too little), Motion, and Employee Creativity. Increasing the velocity of processes is not about working faster, but speeding up the entire end-to-end process or lead time. Think of lead time as the time it takes once you order a book from Amazon to the time you receive the book.

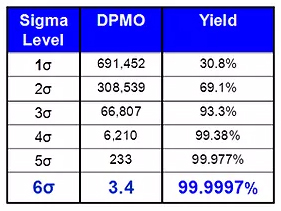

Six Sigma is a well defined, customer focused management system that strives for the delivery of near-perfect products or services. Six Sigma’s goals are to reduce defects and variation so that processes are more consistent and predictable. Originated by Motorola in the 1980s, Six Sigma translates into 99.9997 percent quality or yield. Dial tone of traditional landline phones, for example, was designed to be available 99.9997 percent of the time. Like Lean, Six Sigma places the customer first. It embraces data to make sound decisions. What has made Six Sigma so popular is the money it has saved companies. According to Praveen Gupta, “Companies have reported saving in the billions of dollars. No other methodology comes close to Six Sigma for savings.”

What is “sigma”? The Greek letter Sigma (σ) is a statistical term that measures standard deviation or how far a given process deviates from perfection. The “six” comes from the goal of fitting six standard deviations between the mean and the nearest customer specification or target. To achieve Six Sigma quality (99.9997%), a process must produce no more than 3.4 defects per million opportunities. A “defect” is anything outside of customer specifications. An “opportunity” is defined as the total number of steps in a process where a defect can occur. The central idea behind Six Sigma is that if you can measure how many defects you have in a process, you can systematically figure out how to eliminate them and get as close to zero defects as possible. This means we need to be nearly flawless in executing our key processes. See Table 1:

Table 1.

NOTE by John Dennis, Master Black Belt and Director of Lean Six Sigma Training Ltd:

There is a lot of confusion around why is is called ‘Six Sigma’ and where this number 3.4 DPMO comes from and the 99.9997% yeild. The

defect rate for a process measured over the short term that was producing output parts with a mean centred between the Specification Limits and six standard deviation on either side of the mean from the specification limits would be 2 defects per billion. However Motorola observerd in their processes an average long term drfit/shift of the mean by up to 1.5 standard deviations, therefore they came up with another set of numbers (based on the Empirical rule of Normal Distribution) as shown in the Table 2. However you should not waste time trying to undestand or use this becauseit only applied to Motorola’s processes.

Table 2. Courtesy of the American Society of Quality : ASQ http://asq.org/img/qp/093123_table1.gif

The best way to describe Sigma may be in terms of human behavior. When we start a new job, enter college, enroll in a training program, open up a new business or even try a new sport, humans generally are operating between 1.5 and 2.0 Sigma on a scale of 0 to 6. In other words, people begin by making errors about 30 to 50% of the time. We learn from our errors, and then improve our performance to an acceptable level. Type “A” personalities strive for 3+ Sigma performance or an error level 5% or less. They’re asking questions, taking notes, and practicing their skills. Human behavior can be pushed to Sigma levels above 4 through simple checklists, mistake-proofing or poka-yoke techniques, visual management, and standardized work. Only through machine automation can we can achieve nearly error-free performance to the level of 6 Sigma.

Six Sigma follows a proven, closed-loop framework for tackling problems. It consists of five phases known as DMAIC: Define, Measure, Analyze, Improve, and Control. One of the key tenants that makes this framework work is the methodical discipline of identifying the most significant root causes of a problem before implementing solutions.

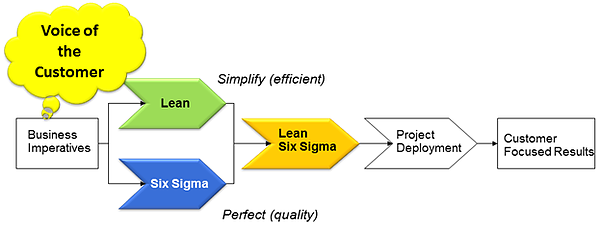

When we combine Lean and Six Sigma, we get something powerful — a business improvement methodology that maximizes shareholder value by achieving the fastest rate of improvement in Cost, Quality and Customer Satisfaction. It focuses on reducing waste by streamlining operations and reducing defects (i.e., services not delivered on-time or within budget). See Figure 1 below.

Peter J. Sherman holds a Master’s Degree in Civil Engineering from the Massachusetts Institute of Technology and an MBA from Georgia State University. From 2008 to 2011, Peter served as Lead Instructor for Emory University’s Six Sigma Certificate program in Atlanta. Peter is a Certified Lean Six Sigma Master Black Belt, ASQ Certified Quality Engineer and an APICS Certified Supply Chain Professional

Lean Six Sigma Training Ltd partners with Robiquity.com to also provide training, coaching and consultint in RPA, Control Room Management, Workforce Augmentation, Blue Prism Training, Automation Academy, Automation Anywhere Training, UiPath Training, Virtual Workforce, Process Automation, Automation, and Robotic Process Automation ( ask for more details ).